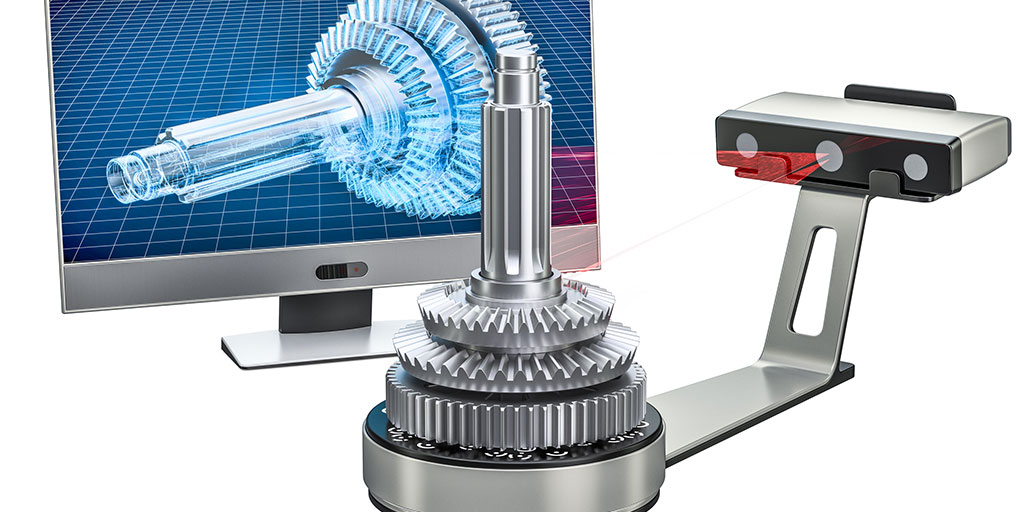

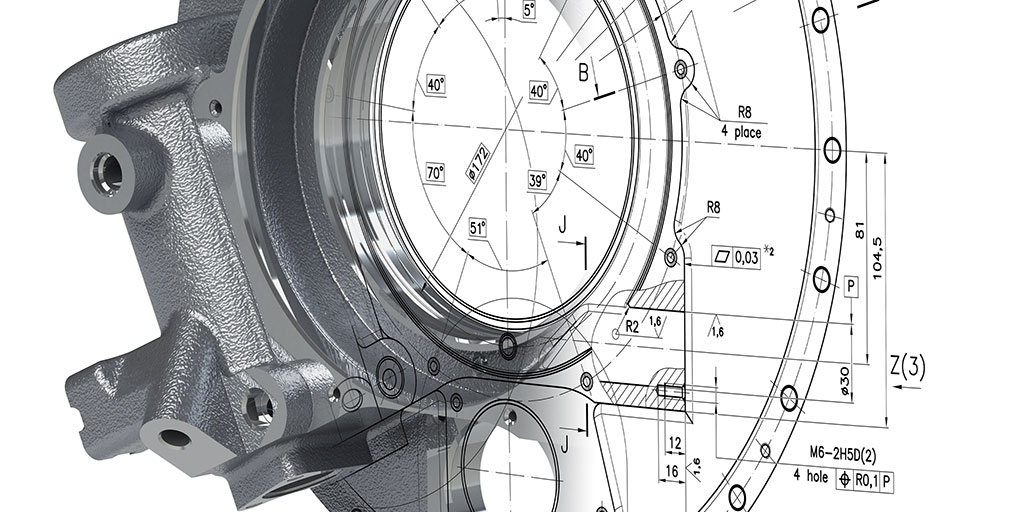

Reverse Engineering is the process of measuring a part using data captured by our 3D scanners; we CAD redesign components for further engineering or remanufacture of existing parts

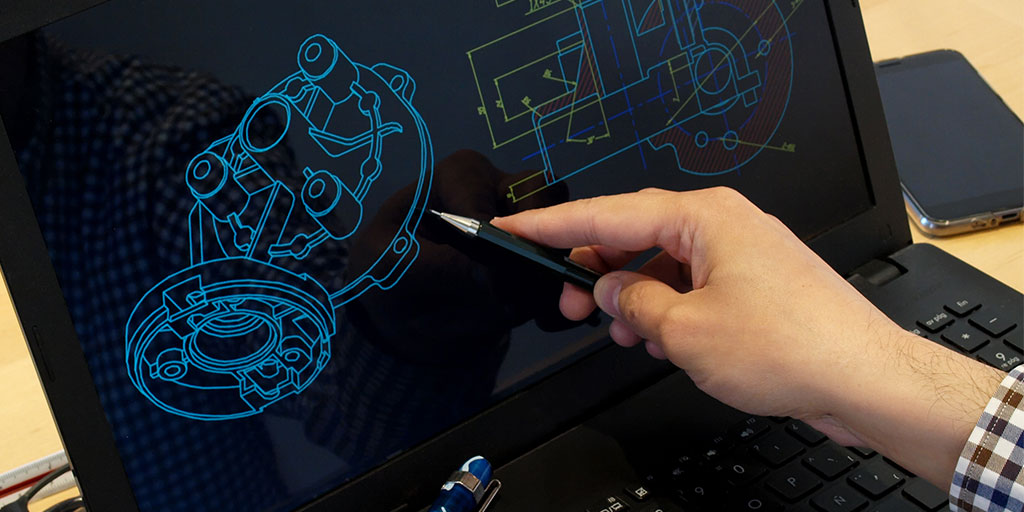

Using Fusion 360, Catia, Solidworks and Solidedge we are able to provide reverse engineering services creating CAD models of damaged or worn parts by extracting the design intent.

We can take a 3D scan and release it as a CAD file ready for further modification, re-manufacture and/or CNC machining. We can input and output data in most industry used formats including: stl, .iges, .step, .asc, .xyz, .txt, .ply, .obj, .3ds, .wrl, .x_t.

If you are not sure on the suitability of 3D printing for your project we can suggest a machining process that can offer an alternative route to manufacture. Often this route can yield an even more impressive result and not at excessively high cost.

If you require prototypes, you’re probably aware that SLS 3D printing is quite possibly the best way to make and test your designs. Unfortunately, SLS printing can be expensive that most businesses can’t afford… this is where Carbotech Ltd can help.