3D printing is a general term used to describe all additive manufacturing technologies.

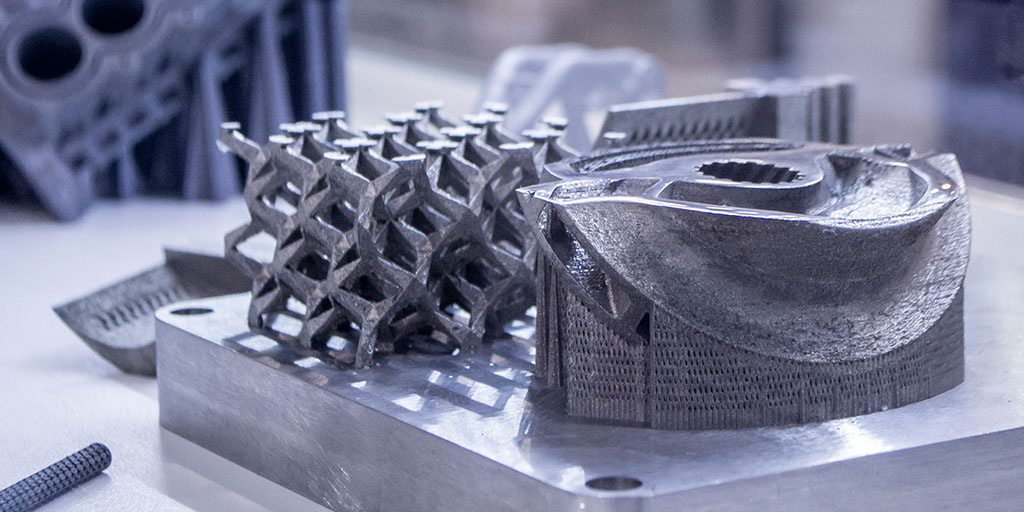

Through 3D printing, objects or parts are built in very thin layers allowing for highly complex geometries that are impossible via any other manufacturing process. 3D printing works best for rapidly creating functional prototypes and end-use parts that are high in detail. There are a number of additive manufacturing technologies available, each with their own advantages based on the layering methodology and material used – with a range of plastics and metals available. The main being fused filament fabrication (FFF), stereolithography (SLA) and selective laser sintering (SLS)

With access to a range of 3D printers we can provide you with a variety of solutions from a simple print to a full colour 3D print in a variety of materials to assist your workflow albeit automotive, aerospace, prototyping, fixturing to name but a few.

Building a part in thousands of thin layers allows the opportunity to create highly complex geometries that are often impossible to mould – internal channels and holes that are unreachable by end mills, or entire assemblies printed as a single piece building prints via STL, VRML and OBJ file format.

Read about 3D Printing Technology in more detail here