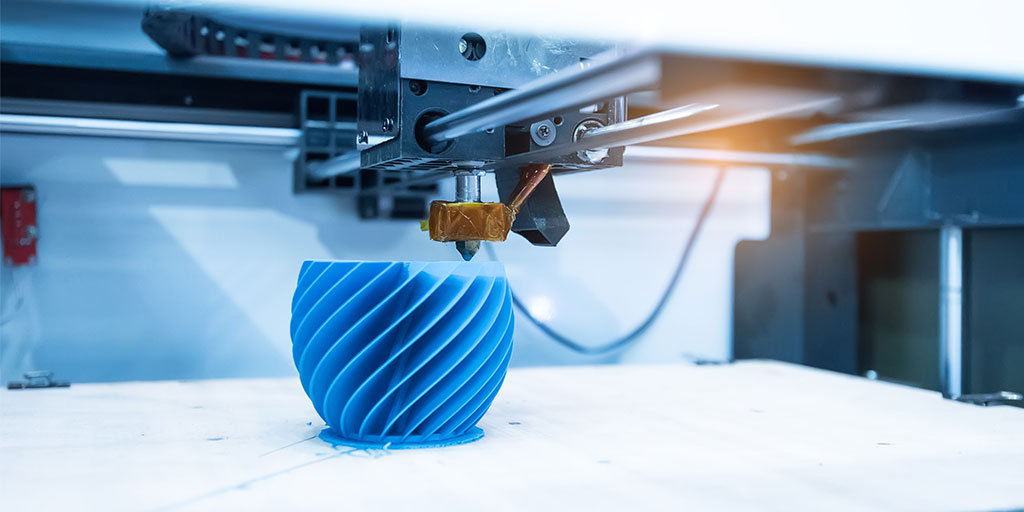

FFF

FFF is the most commonly used 3D printing technology, due to its ease of use and lack of reliance on harsh chemicals. FFF uses a thick string of raw material, commonly referred to as filament. During the FFF process filament is extruded through a heated nozzle, which is mounted on a motion system that moves it around a build area. Melted filament from the nozzle is deposited onto a build plate, where it cools and solidifies to form a layer. The bed then moves down by a fraction of a millimetre to start another layer until the complete object is built.

SLA

Another major 3D printing technology is SLA, which uses a UV-curable resin as a raw material. The resin is poured into a glass-bottomed container, which a build platform is submerged into. A UV laser or DLP projector shines UV light on the resin to selectively harden it into a horizontal layer of the CAD data. The platform then raises out of the container, allowing the uncured resin to level out.

SLS

The third major printing method is SLS, which uses a powdered raw material, typically a polymer. The powder is stored in a container, where a recoating blade distributes a thin layer of material onto the build area. A high powered laser fuses the small particles of material together, in order to form a single horizontal layer of the CAD data. The container then moves a fraction of a millimetre to start a new layer, and a recoating blade swipes across the build area to deposit a new layer of raw material. Unfused powder is recycled by sieving and mixing the sieved powder with unused powder. The process is repeated until a complete object is formed.

Summary

These three major technologies each have their unique benefits. SLA is ideal for small objects with intricate features and details. SLS is ideal for larger, high-volume production and industrial builds. FFF enables businesses to significantly cut development time and costs compared to traditional methods, with FFF processes are more flexible, and involves the least amount of post-processing.